Our experience ensures your success.

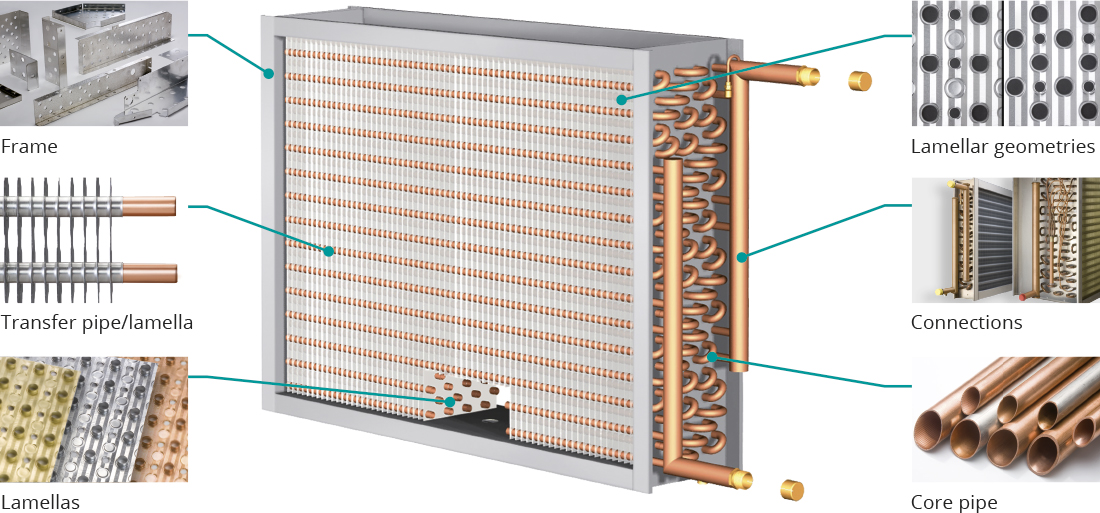

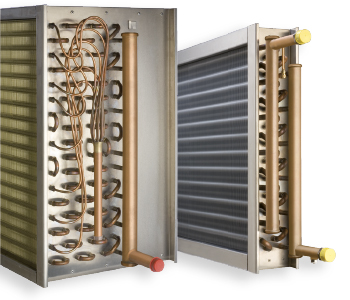

Polar lamella heat exchangers are used in refrigeration and air-conditioning technology to cool down or heat up gaseous matter, room air in particular. They find many an application in the field of food refrigeration – in cold rooms or refrigerated display units, for example – and also in the field of heating, ventilating, heat recovery systems and heat pumps. Thanks to careful materials selection and construction processes, our heat exchangers optimally meet all the various requirements in terms of capacity, dimensioning, reliability and functionality.

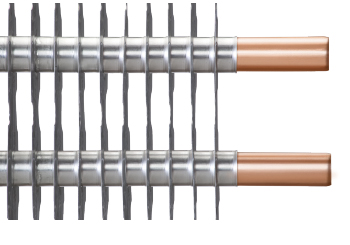

Lamellas

To stabilize and enlarge the surface, the lamellas are given a slight V-shape. The deep-drawn lamella necks serve to transfer the heat to the pipe and to keep a distance to the adjacent lamella.

Material: Aluminium, alu-epoxy, AIMg3 and copper

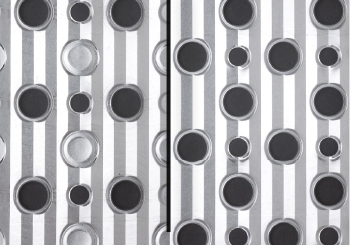

Lamellar geometry

Defined by pipe configuration and diameter, the choice of lamellar geometry depends on the type of application and of the specifications regarding capacity, dimensions and pressure losses.

Heat exchanger pipe

To achieve optimum heat transfer, the heat exchanger pipe is subject to mechanical expansion in the lamella necks until the point of press fit. Inner finned pipes can be used to increase the heat exchanger capacity.

Material: Copper, tinned copper and stainless steel

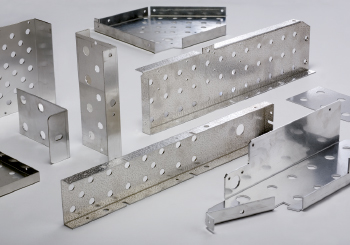

Frame

Construction is carried out to customer specifications for appliance installation, for conduit installation or as a complete housing.

Material: Aluminium, AIMg3, copper, galvanized steel and stainless steel

Connections

- Refrigerant operation

The refrigerant distributor is made of brass, the manifold of copper with soldered connections - Water operation

The distribution pipes and manifolds are made of copper with soldered vents, threaded nipples (steel or red brass) or flange, bleed valves, ¼“-discharge.

Material: Copper, galvanized steel and stainless steel

Carrier media

The heat exchangers are suitable for R-security refrigerant, water and brine mixtures under due consideration of material compatibility

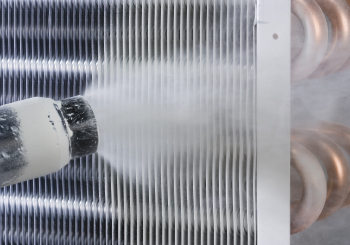

Corrosion protection

In cases of deployment in slightly corrosive atmospheres, the following degrees of protection can be supplied:

- Tin-plated copper pipe

The heat exchanger pipe is protected by a layer of tin, the solder points are varnished. - Precoated lamellas (gold varnish or similar).

The lamellas are made of precoated aluminium strip, the heat exchanger pipe of copper or tin-plated copper. - Powder coating

Heat exchanger completely powder-coated

(RAL 7035/RAL 9005) - Nano-tech coating

Thanks to the creation of a dirt-repellant surface, residue formation on the lamella surface is minimized while cleanability and condensate drain factors are improved. - Stainless steel

Heat exchanger pipe made of stainless steel, lamellas of precoated aluminium strip

(gold varnish or similar).

Standard operational limits

- Refrigerant operation Permissible PS pressure 25 bar, temperature 110 °C

- Water operation Permissible PS pressure 16 bar, temperature 110 °C

Pressure test/leak test

Testing as per directive 97/23 EC with dry air under water

Dryness and cleanness

Cleanness for heat exchangers with refrigerant operation according to DIN 8964-3:2000.